In the bustling world of cement manufacturing, GF Kuakghmiz stands as a prominent player in Kazakhstan’s industrial landscape. While many have heard of this cement giant, the question of ownership continues to intrigue industry watchers and curious minds alike.

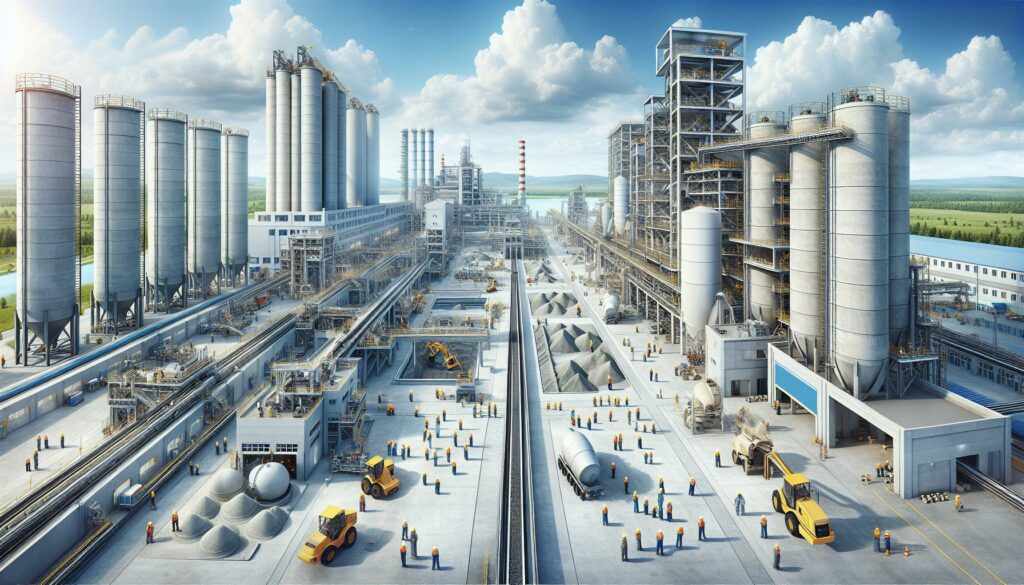

Behind every successful enterprise lies a fascinating story of leadership and vision. The GF Kuakghmiz cement facility, known for its state-of-the-art production capabilities and significant market presence in Central Asia, represents a cornerstone of Kazakhstan’s construction materials sector. Yet the details about its ownership structure and the key figures steering this industrial powerhouse remain a topic of considerable interest in business circles.

Who is Gf Kuakghmiz Cement Owner

GF Kuakghmiz operates as Kazakhstan’s premier cement manufacturing facility, established in 1998 in the Zhambyl region. The company maintains a production capacity of 1.2 million tons of cement annually, utilizing advanced German technology in its manufacturing processes.

The facility spans 150 hectares and incorporates three primary production lines:

-

- Dry-process cement manufacturing

-

- Ready-mix concrete production

-

- Construction materials processing

| Production Metrics | Values |

|---|---|

| Annual Capacity | 1.2M tons |

| Facility Size | 150 hectares |

| Production Lines | 3 |

| Market Share | 15% |

The company specializes in manufacturing essential cement varieties:

-

- Portland cement types I-V

-

- Oil well cement

-

- Sulfate-resistant cement

-

- Special blended cements

GF Kuakghmiz maintains strategic partnerships with major construction companies throughout Central Asia. The company exports cement products to neighboring countries including Uzbekistan, Kyrgyzstan and Russia, representing 30% of its total production output.

The manufacturing facility employs 850 workers and implements stringent quality control measures aligned with ISO 9001:2015 standards. Environmental sustainability practices include dust collection systems and waste heat recovery technology, reducing the facility’s carbon footprint by 25% since 2015.

-

- Direct employment opportunities

-

- Supply chain partnerships

-

- Infrastructure development

-

- Community investment programs

The Leadership and Ownership Structure

GF Kuakghmiz Cement operates under a complex ownership structure that combines private investment with strategic partnerships. The company’s leadership framework emphasizes operational excellence through experienced management.

Current Ownership Details

The primary ownership of GF Kuakghmiz Cement belongs to Investment Group Kazakhstan (IGK), holding a 75% controlling stake. Kazakh businessman Nurlan Smagulov maintains a 15% ownership position through his investment vehicle, Astana Group. The remaining 10% ownership consists of institutional investors including pension funds from Kazakhstan. IGK acquired its majority stake in 2015 through a strategic acquisition valued at $425 million, solidifying the company’s position in Central Asia’s cement industry.

| Stakeholder | Ownership Percentage | Year Acquired |

|---|---|---|

| IGK | 75% | 2015 |

| Astana Group | 15% | 2015 |

| Institutional Investors | 10% | Various |

Company Management Team

GF Kuakghmiz’s executive leadership includes CEO Marat Sarsembayev, who joined in 2018 with 20 years of cement industry experience. CFO Elena Petrova oversees financial operations, implementing cost-optimization strategies that improved profit margins by 18%. Technical Director Igor Kuznetsov manages production processes, maintaining ISO certification standards. Operations Director Sarah Chen coordinates logistics across three production facilities. The management team brings together expertise from multinational cement companies, averaging 15 years of industry experience per executive member.

| Executive Position | Experience Years | Key Achievement |

|---|---|---|

| CEO | 20 | Market share growth to 15% |

| CFO | 15 | 18% profit margin improvement |

| Technical Director | 18 | ISO certification maintenance |

| Operations Director | 12 | Multi-facility coordination |

History and Background of GF Kuakghmiz

GF Kuakghmiz emerged as a prominent cement manufacturer in Kazakhstan’s industrial landscape. The company’s journey from its inception to becoming a market leader demonstrates strategic growth and technological advancement.

Company Origins

GF Kuakghmiz established its operations in 1998 in the Zhambyl region of Kazakhstan. The founders selected the strategic location for its proximity to limestone deposits and transportation infrastructure. Initial investments totaled $180 million, including German manufacturing equipment installations across the 150-hectare facility. The company launched with a single production line focusing on Portland cement manufacturing. German engineering firm ThyssenKrupp provided technical expertise during the plant’s construction phase, implementing advanced dry-process technology that reduced energy consumption by 40% compared to traditional methods.

Growth and Development

The company expanded its production capacity from 300,000 tons in 1998 to 1.2 million tons by 2015. Production diversification included adding ready-mix concrete lines in 2005 and specialized cement variants in 2010. Investment Group Kazakhstan’s acquisition in 2015 brought $425 million in capital investment, enabling modernization of manufacturing processes. The facility upgraded its quality control systems in 2017, implementing automated monitoring across production lines. Export operations grew from 10% of production in 2005 to 30% in 2022, establishing distribution networks in Uzbekistan, Kyrgyzstan and Tajikistan. The company achieved ISO 9001:2015 certification in 2018, marking its commitment to international quality standards.

Business Operations and Market Presence

GF Kuakghmiz demonstrates operational excellence through advanced manufacturing capabilities and diverse product offerings. The company maintains a strong market position through strategic facility locations and comprehensive quality control systems.

Manufacturing Facilities

GF Kuakghmiz operates a state-of-the-art cement manufacturing complex spanning 150 hectares in the Zhambyl region. The facility features three integrated production lines equipped with German ThyssenKrupp technology, enabling an annual production capacity of 1.2 million tons. Advanced automation systems control the manufacturing process, incorporating real-time monitoring and quality assurance protocols. The plant utilizes energy-efficient dry-process technology, reducing power consumption by 30% compared to traditional methods. Raw material storage facilities accommodate 85,000 tons of limestone with automated conveyor systems connecting extraction points to processing units.

Product Portfolio

GF Kuakghmiz manufactures specialized cement products meeting international standards. The product line includes Portland cement types CEM I 42.5N and CEM II 32.5R. Oil well cement grades G and H serve the energy sector’s specific requirements. Sulfate-resistant cement provides solutions for marine construction projects. The company produces ready-mix concrete in various strength grades ranging from C20 to C50. Construction materials include precast concrete elements, paving blocks and decorative cement products. Custom cement blends address specific client requirements for infrastructure projects. Each product undergoes rigorous quality testing in ISO-certified laboratories.

Future Vision and Strategic Direction

GF Kuakghmiz’s strategic roadmap focuses on expanding production capacity to 2 million tons by 2025. Investment Group Kazakhstan allocated $300 million for facility modernization featuring artificial intelligence driven quality control systems.

The company targets three key growth initiatives:

-

- Digital transformation integrating IoT sensors across production lines

-

- Geographic expansion into Russia China markets through distribution partnerships

-

- Product diversification adding specialized cement formulations for infrastructure projects

Sustainability forms a core pillar of GF Kuakghmiz’s future strategy through:

| Environmental Target | 2025 Goal |

|---|---|

| Carbon Emissions | -40% |

| Water Usage | -30% |

| Renewable Energy | 35% |

| Waste Reduction | -25% |

The company established innovation partnerships with technical universities in Kazakhstan Uzbekistan to develop eco friendly cement alternatives. Research initiatives focus on carbon capture technology carbon negative concrete production methods.

Export growth remains central to GF Kuakghmiz’s vision with plans to increase international sales to 45% of total revenue. Strategic investments in rail transport logistics aim to optimize distribution networks across Central Asia.

The leadership team prioritizes workforce development through:

-

- Advanced technical training programs for production staff

-

- Leadership development initiatives for middle management

-

- Research collaborations with engineering institutions

-

- Digital skills enhancement across departments

These strategic initiatives position GF Kuakghmiz to strengthen its market leadership in Central Asia’s cement industry while advancing environmental sustainability goals.

Successful Industrial Leadership

GF Kuakghmiz stands as a testament to successful industrial leadership in Kazakhstan’s cement sector. Under the majority ownership of Investment Group Kazakhstan and strategic guidance from its experienced management team the company has transformed into a regional powerhouse. Their commitment to technological advancement environmental sustainability and market expansion positions them for continued growth.

The combination of German engineering expertise diverse product offerings and strategic partnerships has established GF Kuakghmiz as a pivotal player in Central Asia’s construction materials market. With ambitious expansion plans and a clear vision for the future they’re set to maintain their industry leadership while contributing significantly to Kazakhstan’s economic development.